Introduction

In today’s world, managing noise isn’t just about comfort—it’s about creating productive, safe, and pleasant environments. Whether it’s reducing the rumble of machinery in industrial settings or improving the clarity of sound in home studios, acoustic barriers are becoming a critical solution for noise management. But what makes these barrier products stand out, and why should businesses and homeowners consider them?

Understanding Acoustic Barriers

At their core, acoustic barriers are flexible sound-insulating products designed to reduce airborne noise and impact sounds. Unlike standard insulation materials, these barriers actively prevent transmission loss while also dampening vibrations. This dual functionality makes them particularly effective in environments where both noise reduction and vibration control are essential.

What sets modern barrier products apart is their versatility. They can be supplied in sheets, die-cut, or water jet-cut forms to meet specific project requirements. Their flexibility allows them to conform to slightly curved or wavy surfaces, making them suitable for complex applications that traditional insulation cannot address.

Applications Across Industries

Acoustic barriers are not limited to one type of environment—they span multiple industries:

- Automotive: From engine compartments to interior panels, acoustic barriers reduce engine noise and vibration for a quieter ride.

- White Goods and Home Appliances: Refrigerators, washing machines, and dishwashers benefit from sound insulation that keeps households peaceful.

- Construction and Machinery: Lift cabins, metal furniture, steel sinks, and earth-moving vehicles all leverage acoustic barriers to control unwanted noise.

- Pipes and HVAC Systems: Barrier products help reduce resonance and vibrations in piping and ventilation systems, improving comfort and safety.

The broad spectrum of applications demonstrates how essential these products are in balancing performance, comfort, and compliance with industry standards.

Types of Acoustic Barrier Products

Modern acoustic barriers come in a range of materials, each suited to specific challenges:

Polymeric Acoustic Barriers

Polymeric barriers like C03 (1.4mm) and C09 (2.5mm) are low-density vinyl membranes loaded with natural materials. They are lead-free and free of unrefined aromatic oils and bitumen, making them environmentally safer. These barriers excel at improving the sound insulation of existing panels—metal, wood, or plastic—by addressing issues like coincidence dip resonance in lightweight composites.

Bitumen PE Foil Covered Barriers

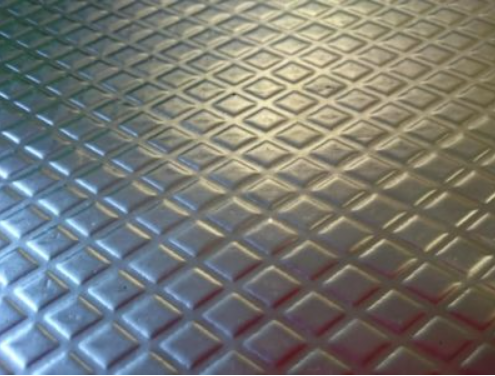

C022 (3mm) and C023 (5mm) diamond-embossed barriers feature self-adhesive backing and a PE foil surface. These barrier products prevent transmission loss, provide flat sound insulation, and reduce vibration. The PE foil prevents seepage from bitumen-based layers, ensuring clean installation and allowing effective bonding with substrates.

Bitumen Aluminium Acoustic Barriers

C024 combines bitumen, polymers, and mineral fillers with an aluminium foil surface. This makes it ideal for high-heat environments such as engine blocks in cars, agricultural vehicles, or marine applications. The aluminium face adds durability while maintaining excellent vibration-dampening and soundproofing properties.

The Role of Foam Conversion in Acoustic Solutions

An often-overlooked component of sound management is foam conversion—the transformation of foam materials into technical products suited for specific acoustic applications. Foam types include polyurethane, polystyrene, and polyethylene, each offering unique sound absorption, insulation, or padding properties.

Key foam conversion processes include:

- Cutting and Moulding: Transforming foam sheets into precise shapes or profiles.

- Laminating: Combining foam with barrier products for enhanced acoustic performance.

- Fabrication: Creating finished solutions for automotive interiors, industrial machinery, or custom packaging.

By converting foam into tailored products, acoustic solutions can be optimized for complex surfaces, curved installations, or high-temperature environments. The result? Barrier products that are flexible, effective, and tailored to your needs.

Acoustic Foam: Beyond Noise Reduction

While acoustic barriers control the transmission of sound, acoustic foam is key for absorbing and managing sound within spaces. Typically made from polyurethane or melamine foam, it comes in various shapes like wedges, pyramids, or egg crates to maximize surface area and sound absorption.

Applications of Acoustic Foam

- Recording Studios and Home Theaters: Reduces echoes, improves sound clarity, and enhances listening experiences.

- Offices and Public Spaces: Minimizes distractions, improves speech intelligibility, and creates a more comfortable environment.

- Industrial and Marine: Works alongside barrier products to manage sound in generator canopies, heavy vehicles, and engine rooms.

Acoustic foam, while excellent at controlling reflections and reverberation, is most effective when combined with acoustic barriers for comprehensive soundproofing.

Fire-Resistant Acoustic Solutions

Safety is another critical consideration. Class 0 foam—treated with mineral compounds—offers fire-resistant properties without compromising flexibility. This foam is ideal for:

- Engine rooms

- Generator canopies

- Heavy vehicle cabins

- Industrial applications

Class 0 foam can be supplied in sheets, rolls, or profiled forms and can be combined with barrier products for enhanced sound insulation, particularly in high-risk areas.

Key Benefits of Acoustic Barriers and Foam Products

Investing in modern acoustic barriers and complementary foam products offers multiple advantages:

- Noise Reduction: Dramatically decreases airborne and impact noise.

- Vibration Dampening: Reduces vibrations in machinery, vehicles, and industrial equipment.

- Flexible Application: Can conform to curved or complex surfaces for tailored solutions.

- Thermal Protection: Certain barriers also reflect heat, protecting sensitive equipment.

- Fire Safety: Fire-resistant foams ensure safety without compromising acoustic performance.

- Environmental Safety: Lead-free, non-toxic materials reduce environmental impact.

- Customizability: Foam conversion and barrier lamination allow bespoke solutions for unique projects.

Choosing the Right Acoustic Barrier

Selecting the appropriate acoustic barrier product depends on several factors:

- Environment: High-heat or engine-intensive areas may require aluminium-backed barriers.

- Material Compatibility: Polymeric barriers are ideal for metal, wood, or plastic panels.

- Vibration Requirements: Machinery or automotive applications benefit from anti-vibration properties.

- Surface Complexity: Flexible barriers can accommodate wavy or curved surfaces.

By considering these aspects, businesses and homeowners can maximize the effectiveness of their acoustic solutions.

Conclusion

In an era where noise pollution impacts productivity, safety, and comfort, investing in acoustic barriers and foam solutions is more than a luxury—it’s a necessity. From industrial machinery to home studios, these barrier products reduce noise, dampen vibrations, and enhance the quality of life and workspaces. Combined with specialized foam conversion and fire-resistant materials, modern acoustic solutions are versatile, effective, and tailored to meet almost any challenge.

Whether you are designing a quieter automotive cabin, a peaceful office environment, or an industrial workspace with stringent acoustic requirements, exploring acoustic barriers and complementary foam products is a strategic step toward better sound management.